Brownsville fleet managers prioritize reliable truck suspension repair equipment due to the city's challenging urban roads and varied terrain. Investing in top-tier recovery tools, like powerful tow trucks and advanced diagnostic software, ensures swift roadside assistance, minimizes downtime, reduces repair costs, and enhances overall fleet safety and reliability. Regular inspections and timely repairs are crucial to prevent increased downtime and higher operational costs, especially considering Brownsville's warm, moist climate that accelerates corrosion and wear. Proper maintenance, adherence to safety protocols, and using the right tools extend equipment lifespan and enhance recovery operation efficiency.

Brownsville fleet operations rely heavily on reliable recovery equipment for safe and efficient truck suspension repair. This article explores the critical role these tools play in addressing common issues afflicting fleet vehicles, ensuring seamless logistics. From understanding essential equipment like jacks and winches to selecting the right fit for your fleet and maintaining safety protocols, we provide a comprehensive guide to optimizing your Brownsville fleet’s resilience and longevity.

- Understanding Recovery Equipment: Essential Tools for Fleet Maintenance in Brownsville

- The Role of Truck Suspension Repair in Ensuring Safe Operations

- Common Issues with Fleet Vehicles and Their Impact on Logistics in Brownsville

- Types of Recovery Equipment: From Jacks to Winches

- Selecting the Right Recovery Equipment for Your Brownsville Fleet

- Maintenance and Safety Protocols for Effective Longevity of Recovery Tools

Understanding Recovery Equipment: Essential Tools for Fleet Maintenance in Brownsville

Brownsville fleet managers recognize the importance of having reliable recovery equipment for effective truck suspension repair. This specialized gear plays a pivotal role in ensuring swift and efficient roadside assistance, minimizing downtime for vehicles crucial to the city’s bustling logistics network. With Brownsville’s landscape boasting dense urban areas and expansive highways, having access to robust recovery tools is essential for maintaining fleet efficiency and safety standards.

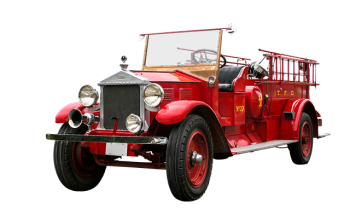

The range of recovery equipment includes powerful tow trucks, specialized lifting gear, and advanced diagnostic tools tailored for truck suspension repairs. These assets enable mechanics to tackle a variety of issues, from minor accidents to significant damage, promptly and effectively. By investing in top-tier recovery equipment, Brownsville fleet operators can enhance their response times, reduce repair costs, and contribute to the overall reliability of their vehicle fleets.

The Role of Truck Suspension Repair in Ensuring Safe Operations

Brownsville fleet operations rely heavily on the reliable functioning of their vehicles. Among various maintenance aspects, truck suspension repair plays a pivotal role in ensuring safe and efficient operations. A well-maintained suspension system is crucial for several reasons:

It directly impacts driver safety by providing stability and control over the vehicle, especially during sudden maneuvers or adverse weather conditions. A compromised suspension can lead to reduced traction, prolonged braking distances, and increased risk of accidents. Moreover, regular truck suspension repair helps extend the lifespan of other critical components like tires, brakes, and steering systems, as it keeps the overall mechanical condition of the vehicles optimal. By addressing suspension issues promptly, Brownsville fleet managers contribute to maintaining a high level of operational safety and reliability.

Common Issues with Fleet Vehicles and Their Impact on Logistics in Brownsville

Brownsville, a bustling metropolis in Texas, faces unique challenges when it comes to maintaining its fleet vehicles, especially those used for logistics and transportation. One of the primary issues is the demanding nature of local roads, which often include both dense urban areas and more remote, rougher terrain. This puts significant strain on truck suspension systems, leading to frequent repairs and maintenance needs.

Brownsville fleet truck suspension repair is a critical aspect of keeping logistics running smoothly. Delayed maintenance can result in increased downtime for vehicles, impacting delivery schedules and driving up operational costs. Moreover, the region’s warm, moist climate contributes to corrosion and wear on parts, making regular inspections and timely repairs even more crucial. Professional mechanics play a vital role in addressing these common issues, ensuring that fleet vehicles remain reliable and safe for Brownsville’s dynamic logistics landscape.

Types of Recovery Equipment: From Jacks to Winches

When it comes to fleet truck suspension repair in Brownsville, the right recovery equipment is a vital tool for any mechanic or automotive professional. From basic jacks to advanced winches, each piece serves a unique purpose and plays a crucial role in ensuring efficient and safe vehicle lifting and movement.

Jacks, for instance, are compact and versatile, ideal for quick temporary lifts. They come in various types, from hand-operated models to hydraulic jacks, capable of handling different weight capacities. On the other end of the spectrum, winches offer more power and precision, making them perfect for heavier trucks or complex suspension repairs. Modern winches often feature advanced features like remote controls, allowing for safer and easier operation. These equipment options form a diverse fleet that caters to various repair needs, ensuring Brownsville’s fleet truck suspension repair services are both effective and efficient.

Selecting the Right Recovery Equipment for Your Brownsville Fleet

Selecting the right recovery equipment for your Brownsville fleet is a crucial decision. Consider factors like vehicle types, common recovery scenarios, and budget when making your choice. For instance, if your fleet primarily deals with truck suspension repairs, invest in equipment specialized for heavy-duty recoveries, like powerful winches capable of handling substantial weight and specialized lifting gear designed for safe, secure vehicle stabilization. By aligning your equipment with the specific needs of your Brownsville fleet, you can ensure efficient operations, minimize downtime, and maximize safety on the road.

Maintenance and Safety Protocols for Effective Longevity of Recovery Tools

Proper maintenance and adherence to safety protocols are paramount for ensuring the longevity and effectiveness of recovery equipment. Regular inspections, such as those conducted on Brownsville fleet truck suspension repair systems, should be scheduled at predetermined intervals to identify and address potential issues early. This proactive approach prevents minor problems from escalating into costly repairs or safety hazards.

Safety precautions, including proper training for operators and adherence to manufacturer guidelines, are essential. Using the right tools and techniques during maintenance procedures not only extends the lifespan of equipment but also enhances the overall efficiency of recovery operations. For instance, maintaining a well-calibrated suspension system in Brownsville’s fleet can significantly improve the safety and responsiveness of trucks during rescue missions.

Understanding the importance of recovery equipment is vital for maintaining the safety and efficiency of your Brownsville fleet. By investing in the right tools, such as truck suspension repair kits and winches, you can effectively address common vehicle issues and prevent disruptions to your logistics operations. Remember that regular maintenance and adherence to safety protocols are key to ensuring the longevity and optimal performance of these essential recovery tools.