In Brownsville, selecting the right master cylinder is crucial for optimal performance and safety when equipping fleet trucks with off-road accessories. There are two main types: hydraulic for heavy-duty applications and pneumatic for quicker response times. Fleet owners should consider accessory type, power requirements, and lifting capacity to choose the best fit. Proper installation, regular maintenance, and high-quality fluids enhance safety and performance in challenging terrains. Master cylinders play a vital role in safe and efficient trucking and off-road operations, with advancements focusing on improved precision, durability, and control for modern vehicles.

Master cylinders are essential components for both fleet trucks and off-road vehicles, providing reliable hydraulic power for braking systems. This comprehensive guide explores the fundamental function, diverse types, and critical considerations for selecting, installing, maintaining, and upgrading master cylinders in demanding environments. We delve into real-world applications, highlighting successful implementations in truck fleets and off-road adventures. Additionally, we gaze into the future, discussing innovative trends shaping the market for fleet trucks and off-road accessories in Brownsville and beyond.

- Understanding Master Cylinders: The Basic Function and Types for Fleet Trucks and Off-Road Vehicles

- Choosing the Right Master Cylinder for Your Off-Road Accessories in Brownsville

- Installation and Maintenance Tips for Optimal Performance in Harsh Environments

- Case Studies: Real-World Applications of Master Cylinders in Truck Fleets and Off-Road Adventures

- The Future of Master Cylinders: Innovations and Trends Shaping the Market

Understanding Master Cylinders: The Basic Function and Types for Fleet Trucks and Off-Road Vehicles

Master cylinders are essential components in both fleet trucks and off-road vehicles, playing a critical role in their braking systems. These devices convert the force applied by the driver’s brake pedal into hydraulic pressure, which is then used to slow or stop the vehicle’s wheels. Understanding how master cylinders function and the different types available is crucial for maintaining optimal braking performance and safety, especially in demanding off-road conditions or when managing a fleet of trucks in Brownsville.

In fleet trucks and off-road vehicles, there are typically two main types of master cylinders: hydraulic and pneumatic. Hydraulic master cylinders use fluid pressure to multiply the force applied by the brake pedal, making them suitable for heavy-duty applications. Pneumatic master cylinders, on the other hand, rely on compressed air, offering faster response times but generally less powerful braking. Choosing the right type depends on the specific needs of the vehicle and operational environment, ensuring efficient braking and enhanced safety features for Brownsville-based fleet trucks and off-road adventures.

Choosing the Right Master Cylinder for Your Off-Road Accessories in Brownsville

When equipping your fleet truck with off-road accessories in Brownsville, selecting the appropriate master cylinder is a critical component to ensure optimal performance and safety. The right master cylinder boosts control and responsiveness, enhancing your vehicle’s capabilities on rough terrains. Consider factors like the type of accessories you’re installing, their power requirements, and the overall lifting capacity needed.

For instance, if you’re adding heavy-duty winches or lift kits, a high-flow master cylinder may be necessary to handle the increased hydraulic demands. Conversely, lighter modifications might suffice for smaller accessories. Local experts in Brownsville can guide fleet owners through this process, ensuring they choose master cylinders aligned with their specific off-road accessory needs.

Installation and Maintenance Tips for Optimal Performance in Harsh Environments

When installing master cylinders for fleet truck off-road accessories in Brownsville, it’s crucial to ensure proper alignment and secure mounting. This is especially important in harsh environments where extreme temperatures and rough terrain can put added strain on brake systems. A professional installation by experienced mechanics familiar with local conditions is highly recommended.

Regular maintenance is equally vital. Keep an eye on fluid levels, check for leaks, and replace worn-out parts promptly. In challenging off-road settings, consider using high-quality fluids designed to withstand extreme conditions. Additionally, inspect the master cylinder for any signs of damage or corrosion, as these can negatively impact performance and safety. Such proactive measures will ensure your fleet trucks’ brakes remain reliable and effective, enhancing both driver safety and overall off-road performance.

Case Studies: Real-World Applications of Master Cylinders in Truck Fleets and Off-Road Adventures

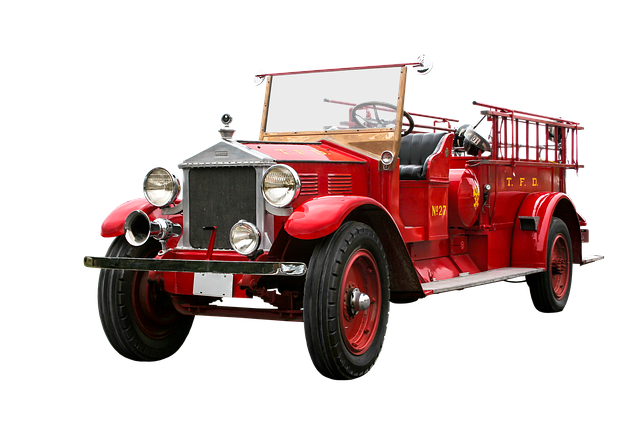

In the world of trucking and off-road exploration, master cylinders play a vital role in ensuring smooth and safe operations. Fleet truck owners and off-road enthusiasts alike rely on these components to control and regulate hydraulic systems, enabling versatile functionality. For instance, in Brownsville, Texas, local fleet managers have witnessed significant improvements in their vehicle performance after integrating advanced master cylinder technologies. These upgrades have not only enhanced the trucks’ stopping power but also improved overall driving dynamics, especially in challenging terrain.

Off-road adventures, whether it’s traversing rugged mountains or navigating muddy trails, demand robust hydraulic systems. Master cylinders designed for such applications often feature durable construction and precise control mechanisms. They enable drivers to manage heavy equipment attachments, such as winches or lifting arms, with ease. By prioritizing the right master cylinder upgrades, off-road enthusiasts can enhance their fleet’s capabilities, making each adventure safer and more enjoyable.

The Future of Master Cylinders: Innovations and Trends Shaping the Market

The master cylinder, a vital component in vehicle braking systems, is seeing significant advancements driven by evolving demands from various sectors, including fleet truck and off-road applications in Brownsville and beyond. These innovations are not only enhancing safety but also improving performance and reliability, catering to the diverse needs of modern vehicles.

Trends indicate a shift towards more sophisticated hydraulic systems, integrating advanced materials and designs to meet the stringent requirements of today’s automotive market. As technology advances, we can expect master cylinders that offer enhanced precision, improved durability, and better control, especially relevant for off-road vehicles navigating challenging terrains. This future looks promising, with continuous developments tailored to keep pace with the ever-growing demand for efficient, reliable, and safe braking solutions in both on and off-road settings.

Master cylinders play a pivotal role in ensuring safe and efficient operations for both fleet trucks and off-road vehicles. By understanding their basic functions, diverse types, and crucial role in extreme environments, owners and mechanics can make informed decisions when selecting and maintaining these components. Choosing the right master cylinder for your specific off-road accessories in Brownsville is essential, as it directly impacts performance and safety. With ongoing innovations and market trends focusing on enhanced durability and improved technologies, the future of master cylinders looks promising, offering even better solutions for various applications, especially within the fleet truck and adventurous off-road sectors.