Rotor discs, core components of RGV (Radial Gauge Vehicle) wheels and tires, are vital for high-performance and longevity in extreme conditions. Crafted from materials like cast iron or specialized alloys, they manage intense friction and heat. Their design includes vents and slots to prevent overheating and maintain consistent performance. Regular maintenance, including wheel alignment checks, tire pressure monitoring, and wear assessments, prolongs the life and optimal performance of RGV systems, focusing on rgv wheels and tires. Material selection varies from affordable cast iron to premium carbon fiber options for enhanced braking efficiency and reduced weight in high-performance applications.

In the realm of high-performance vehicles, understanding the core components driving their power is paramount. Rotors, a vital element within RGV (Rotor-Guided Vehicle) wheels and tires, play a crucial role in enhancing speed, stability, and overall efficiency. This article delves into the intricacies of rotors, exploring different types and materials that define their performance. We also provide essential insights on maintenance and care to ensure longevity and optimal RGV system functionality.

- Understanding Rotors: The Core Component of RGV Wheels and Tires

- Types and Materials: Choosing the Right Rotor for Your Vehicle

- Maintenance and Care: Ensuring Longevity and Performance in RGV Systems

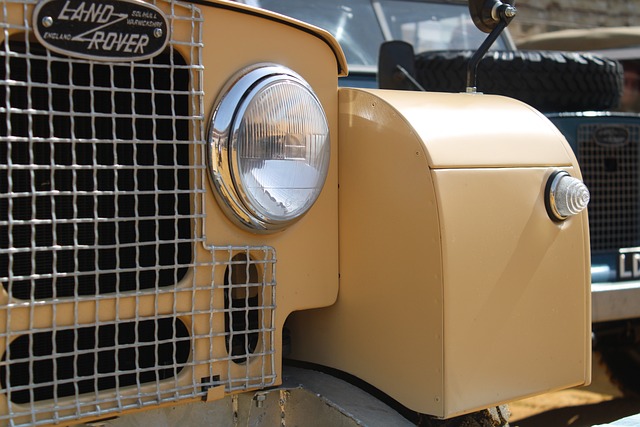

Understanding Rotors: The Core Component of RGV Wheels and Tires

Rotors, or rotor discs, are the heart of RGV (Radial Gauge Vehicle) wheels and tires, playing a pivotal role in their performance and longevity. These components are designed to withstand extreme conditions, ensuring the smooth operation of high-speed vehicles like trains and trams. Each rotor is meticulously crafted from robust materials, such as cast iron or specialized alloys, to handle immense friction and heat generated during motion.

In RGV wheels and tires, rotors serve as the interface between the vehicle’s braking system and the wheels. When brakes are applied, pressure is distributed across the rotor’s surface, enabling efficient deceleration. The unique design of rotors includes vents and slots that facilitate heat dissipation, preventing overheating and ensuring consistent performance, even under heavy loads. Understanding the crucial function of rotors is essential in appreciating the advanced engineering behind RGV wheels and tires.

Types and Materials: Choosing the Right Rotor for Your Vehicle

When it comes to rotors, there are primarily three types: solid, vented, and slotted. Each is designed for different performance needs. Solid rotors offer consistent braking power and heat dissipation, ideal for daily driving. Vented rotors, with their cooling slots, excel in high-performance scenarios where heat build-up can be an issue, ensuring your brakes stay efficient. Slotted rotors are a step further, featuring intricate slits that not only enhance cooling but also reduce vibration and wear, making them popular among those seeking exceptional brake control and longevity, often seen in sports cars and rgv wheels and tires applications.

Choosing the right rotor material is equally crucial. Cast iron is common and cost-effective, providing adequate braking performance for most vehicles. However, for those prioritizing lighter weight and improved thermal properties, aluminum rotors are a superior choice. They offer better heat conductivity, reducing brake fade during intense driving sessions. High-performance drivers often opt for carbon fiber or composite rotors, which deliver exceptional strength-to-weight ratios, enhanced cooling capabilities, and reduced unsprung weight, resulting in more responsive and efficient braking systems—a must for competitive driving or modifying high-performance vehicles with rgv wheels and tires.

Maintenance and Care: Ensuring Longevity and Performance in RGV Systems

Regular maintenance and care are paramount for ensuring the longevity and optimal performance of Rotational Grid Vertical (RGV) systems, particularly focusing on the intricate rgv wheels and tires. A proactive approach involves adhering to a structured maintenance schedule that includes thorough inspections at regular intervals. During these checks, it’s essential to scrutinize wheel alignment, tire pressure, and any signs of wear or damage. Early detection of issues can prevent minor problems from escalating into major, costly repairs.

Proper storage conditions are another critical aspect. Protecting rgv wheels and tires from extreme temperatures, moisture, and direct sunlight slows down the natural degradation process. Additionally, regular cleaning and lubrication of moving parts contribute to smooth rotation and extended component lifespan. By integrating these care practices, users can maximize the efficiency and durability of their RGV systems.

Rotors are the unsung heroes of RGV (radio-controlled vehicle) wheels and tires, providing essential stability and performance. By understanding different rotor types, materials, and proper maintenance techniques, you can ensure your RGV system delivers optimal speed and control. Choosing the right rotors, made from durable materials like carbon steel or aluminum, can extend their lifespan and enhance overall vehicle performance. Remember, regular care and attention to these core components are key to navigating the tracks with precision and confidence in any RGV wheel and tire setup.