RGV wheels are crucial for recovery vehicles, offering superior traction and stability on rough terrain through deep treads, reinforced structures, and optimized air pressure systems. Essential for rescue missions, these wheels enhance team mobility, reducing response times. Material science experts recommend high-grade alloys and optimized tread designs for efficient operations. RGV wheels prioritize safety with advanced materials and designs, ensuring better grip on diverse road conditions. Proper maintenance, including regular inspection and lubrication, prolongs their lifespan. They are versatile, used in various industries from agriculture to construction and electric mobility solutions.

“Unveiling the Power of RGV Wheels: Revolutionizing Recovery Operations

In the realm of heavy-duty recovery, RGV (Recovery and Grid Vehicle) wheels stand as game-changers. This comprehensive guide delves into the intricacies of these specialized wheels, offering a robust foundation for efficient vehicle recovery. From understanding the basic architecture to exploring advanced material science, we unravel the secrets behind stable and safe recovery operations. Discover how the right wheel design, coupled with optimal maintenance, can enhance recovery efficiency and ensure long-lasting performance.”

- Understanding RGV Wheels: A Foundation for Recovery

- The Role of Wheel Design in Stabilizing Recovered Vehicles

- Material Science: Choosing Right Wheels for Efficient Recovery

- Enhancing Safety Measures through Advanced Wheel Technology

- Maintenance Tips to Maximize RGV Wheels' Lifespan

- Real-World Applications: Success Stories of RGV Wheels

Understanding RGV Wheels: A Foundation for Recovery

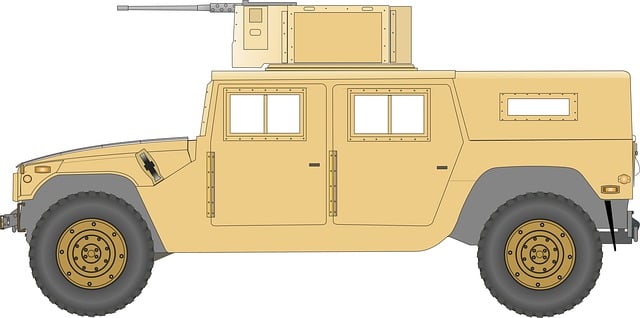

Recovery vehicles, equipped with specialized RGV wheels, play a pivotal role in navigating challenging terrain and accessing remote areas during rescue and recovery operations. These robust wheels are designed to handle extreme conditions, from mud and sand to rocky outcrops, ensuring vital equipment and personnel can reach those in need swiftly and safely.

The unique design of RGV wheels incorporates features like deep tread patterns, reinforced construction, and optimized air pressure systems that enhance traction and stability. This foundation of robust mobility allows rescue teams to efficiently traverse difficult landscapes, ultimately improving response times during critical situations.

The Role of Wheel Design in Stabilizing Recovered Vehicles

The design of wheels plays a pivotal role in stabilizing vehicles during recovery operations, ensuring safer and more efficient rescues. RGV (Recovery Vehicle) wheels are specifically engineered to withstand extreme conditions, featuring robust construction and specialized tread patterns. These designs enable enhanced traction on various terrains, from muddy fields to rugged mountainsides, where traditional wheels might struggle.

The stability afforded by RGV wheels is crucial for managing the weight distribution of recovered vehicles or objects, preventing them from shifting during transport. This feature is especially valuable in emergency situations, ensuring that rescue teams and their equipment remain secure and controllable, even under challenging circumstances.

Material Science: Choosing Right Wheels for Efficient Recovery

In the realm of material science, selecting the right wheels is paramount for efficient recovery operations. The choice of wheels, specifically RGV (Reciprocating Geared Vehicle) wheels, significantly impacts the overall performance and productivity during challenging terrain navigation. These vehicles, designed for robust operations, demand wheels that offer superior traction, durability, and versatility.

When it comes to RGV wheels, several factors must be considered. Material science experts recommend wheels crafted from high-grade alloys, ensuring both strength and flexibility. The tread design plays a crucial role in gripping uneven surfaces, while advanced wheel construction techniques contribute to reduced weight, enhancing maneuverability. By aligning the wheel selection with the specific demands of the recovery mission, operators can ensure optimal performance, minimizing downtime and maximizing efficiency in diverse and demanding environments.

Enhancing Safety Measures through Advanced Wheel Technology

In today’s competitive automotive landscape, enhancing safety is paramount. One area where significant strides have been made is through advanced wheel technology, such as those offered by RGV wheels. These cutting-edge wheels are designed to provide superior traction, stability, and durability, all crucial factors in ensuring driver and passenger safety.

The innovative features integrated into RGV wheels go beyond basic functionality. They incorporate advanced materials and designs that reduce the risk of accidents by improving handling and braking performance. For example, their unique tread patterns and high-quality alloys contribute to better grip on various road conditions, enabling drivers to navigate through challenging environments with greater control. By prioritizing safety and adopting such technological advancements, RGV wheels set a new standard in wheel technology, fostering a safer driving experience for all.

Maintenance Tips to Maximize RGV Wheels' Lifespan

To maximize the lifespan of your RGV wheels, regular maintenance is key. Start by inspecting them for any signs of wear and tear after each use, especially in challenging terrains. Promptly address any issues like cracks, punctures, or bent spokes to prevent further damage.

Keep your RGV wheels clean by wiping them down with a damp cloth after riding, removing mud, dirt, and debris. Ensure proper storage by parking your vehicle on level ground and securing the wheels to avoid curvature or warping. Regular lubricating of moving parts, such as hubs and spokes, will also contribute to their longevity.

Real-World Applications: Success Stories of RGV Wheels

In the real world, RGV wheels have found their niche in various industries, showcasing their versatility and reliability. These wheels, renowned for their sturdy construction and innovative design, have become a game-changer in many applications. From industrial equipment to outdoor recreation vehicles, RGV wheels offer enhanced performance and durability.

One notable success story involves agricultural machinery, where these wheels provide exceptional traction and stability on rough terrain. They are also widely used in construction sites for their ability to withstand harsh conditions. Moreover, in the realm of electric mobility, RGV wheels contribute to smoother rides and extended battery life, making them a preferred choice for eco-friendly transportation solutions.

RGV wheels have emerged as indispensable tools in the recovery industry, offering enhanced stability, durability, and safety. By understanding the science behind their design, material choices, and maintenance practices, professionals can maximize the benefits of these game-changing wheels. The real-world applications highlighted in this article demonstrate the significant impact RGV wheels have on efficient recovery operations, ensuring folks can navigate through challenging situations with greater ease and confidence.